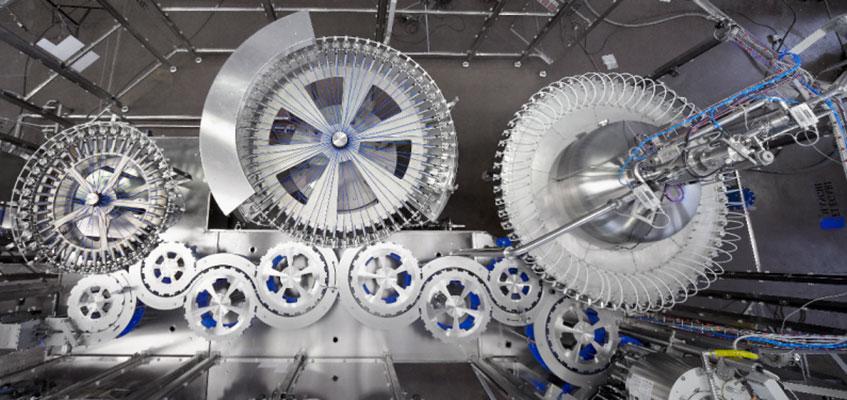

Bottling Lines

With its wide range of industrial and technological solutions, ASIBEX main scope is to take any product from the ideation phase to shelves in markets.

We start by exploring the concept of the product, the supply chain, the production site and the needed machinery before designing the line. Once the line is designed and approved, state-of-the-art machinery to blow, fill, cap and label products along with all necessary and complementary equipments will be at our clients’ disposal.

Over the span of two decades, ASIBEX has gained extensive knowledge of machinery and smart technologies, enabling its staff to select the most appropriate machines that cater to every client’s needs. Not only are the machines efficient and cost-effective, but they can also self-detect any problems and inform users of their needs for maintenance.

While putting the line in place, ASIBEX performs necessary checks and tests, ensuring that the line is safe and fully operational. Furthermore, ASIBEX runs a short-term training program, either on-site or in our own cooperation, class room or with its partners, in order to familiarize the client’s staff with the machinery details.

Because first trials after the installation of the line are critical, ASIBEX helps clients start their lines, ensuring that they adhere to all the necessary conditions.

Implementing this five-step process with due diligence and extensive knowledge of the market, ASIBEX has helped hundreds of clients in the region launch their successful bottling lines. With this well-devised process, inconveniences have been reduced to a minimum, as lines have continued to deliver the quality their brands deserve.